Rudder Skin Riveting Part 1 + Installing Counterweight

Most of the rudder skin is riveted, and the rest of it is prepped for riveting along with installing the counterweight.

We riveted most of the rudder skin, other than the top part, however that part of the skin is also prepped for riveting after the tail light beacon gets installed. The process was pretty straightforward, a few holes needed to be cleaned up though. In preparation for the top skins to be riveted, dimpling and countersinking the fiberglass tip is finished.

Bottom Skin Installation

Installing the bottom skin was mostly straightforward as described in the subsections below.

Assembly

To cleco the top skin, one side was done at a time, for the other side, it required stretching the skin a bit due to precision cut holes, which is a great problem to have.  Clecoing the bottom skin.

Clecoing the bottom skin.  Clecoing the bottom skin.

Clecoing the bottom skin.

Riveting

Once the clecos were in place, riveting was very straightforward.  Bottom skin riveted.

Bottom skin riveted.  Bottom skin riveted.

Bottom skin riveted.

Installing Counterweight

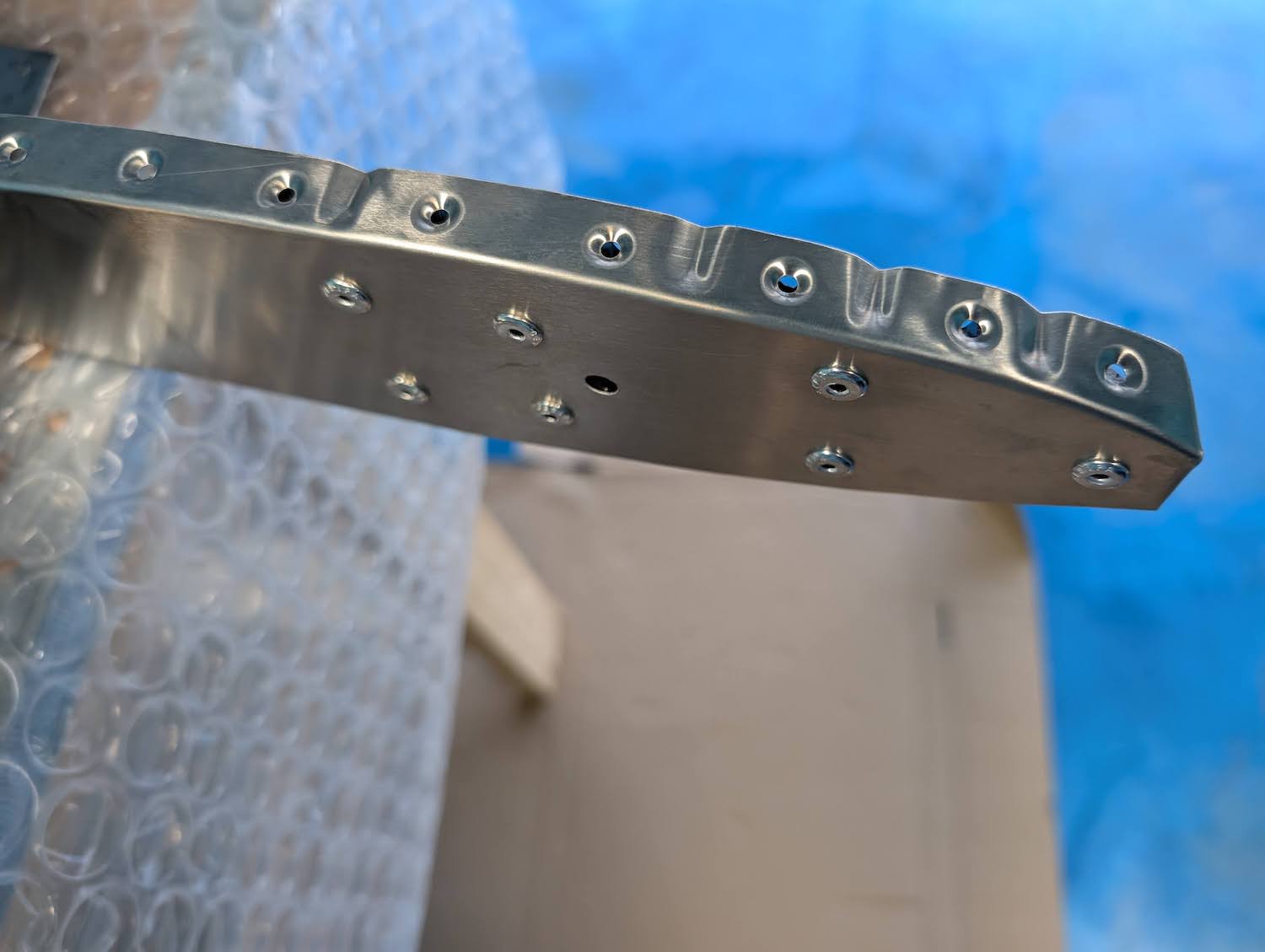

Installing the counterweight required some cleaning up of the holes, before riveting.  Counterweight riveted on the top rib.

Counterweight riveted on the top rib.  Counterweight riveted on the top rib.

Counterweight riveted on the top rib.

Top Skin Preparation

Top skin preparation involved some countersinking as well as dimpling. Additionally, the fiberglass tip also needed holes which were drilled one after the other, while using clecos to keep the holes already drilled in place. Dimpling was done in the end after drilling the holes.

Dimpling

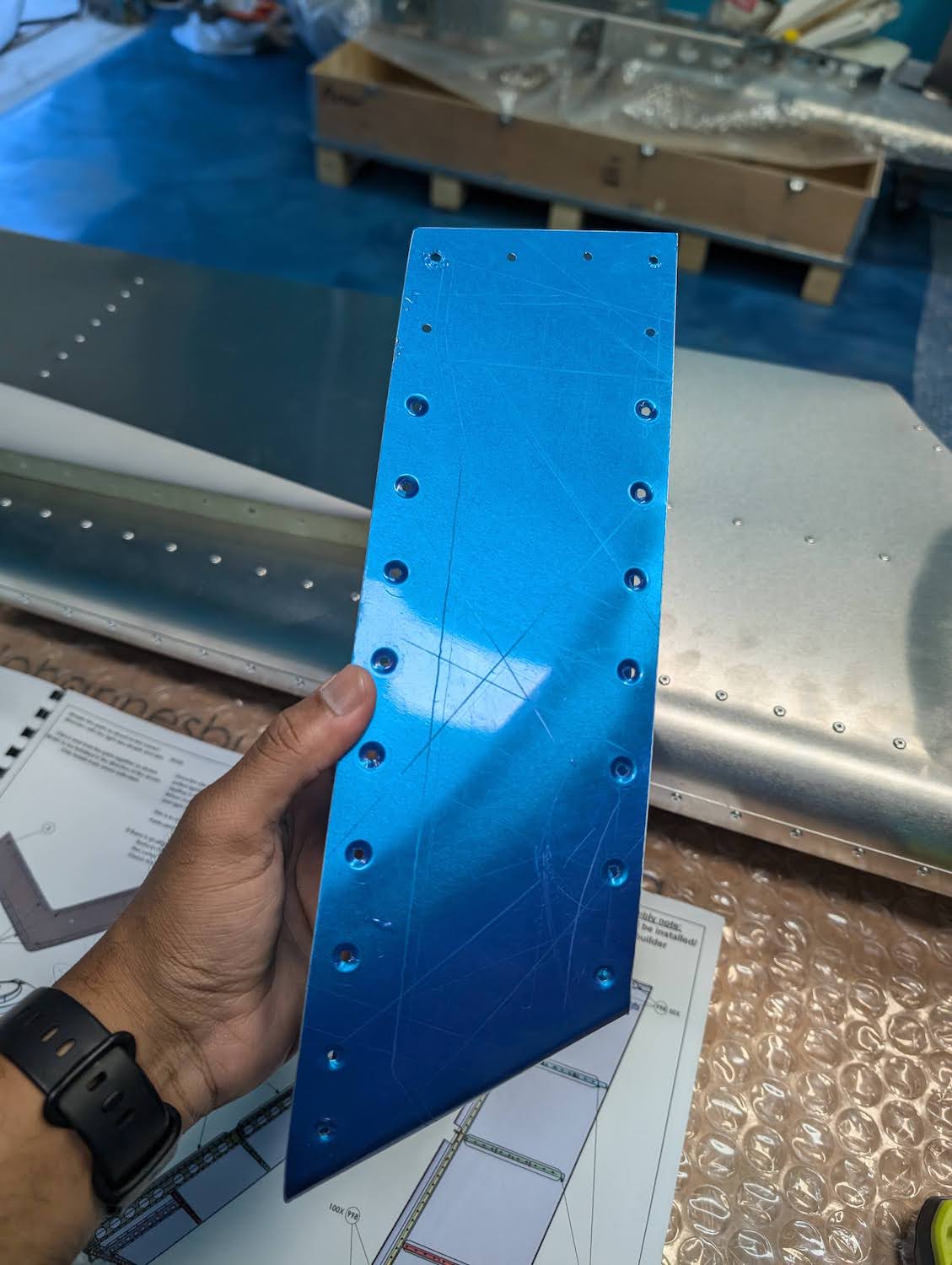

Dimpling was done using the impact dimpler tool as usual.  Top skin dimpled in preparation for riveting.

Top skin dimpled in preparation for riveting.

Countersinking

Countersinking was done using the usual counterstop tool.  Fiberglass tip countersinking.

Fiberglass tip countersinking.

Assembly

The top skins were assembled temporarily using clecos, in preparation for riveting after the tail beacon wiring has been finished.  Top skin assembled temporarily.

Top skin assembled temporarily.

Tools

We ended up ordering a new rivet gun which is very effective so far, especially in collecting the mandrill. Here is the link