Rudder Skin Riveting Part 2 (Final) + Installing Tail Beacon

Rudder skin is completely riveted, and a red tail beacon has also been installed.

We riveted the whole rudder skin, only top one was left from the previous blog. Additionally, red tail beacon was also wired and installed on top of the fiberglass tip.

Tail Beacon Installation

Installing the tail beacon consisted of two parts, the bulb socket itself and the wiring that went with it. We used some epoxy.

Bulb Socket

Installing the bulb socket required some drilling using step drill bits, along with using some epoxy to join the rivnuts to the fiberglass tip. ![]() Holes to accommodate the tail beacon bulb socket.

Holes to accommodate the tail beacon bulb socket. ![]() Red Tail beacon with the bulb and socket.

Red Tail beacon with the bulb and socket. ![]() Rivnuts epoxied to the fiberglass tip.

Rivnuts epoxied to the fiberglass tip. ![]() Rivnuts epoxied to the fiberglass tip.

Rivnuts epoxied to the fiberglass tip. ![]() New holes to rivet the socket.

New holes to rivet the socket. ![]() Bulb socket riveted to the tail fin.

Bulb socket riveted to the tail fin. ![]() Bulb socket riveted to the tail fin.

Bulb socket riveted to the tail fin. ![]() Bulb socket with the bulb and cover attached.

Bulb socket with the bulb and cover attached.

Wiring

Installing the wiring required installing some snap bushings to protect the wires along with braided sleeving. Additionally, solder sleeves with heat shrink were used to join the wires. ![]() Snap bushings installed for the wire holes. New rivets installed on either side for re-enforcement.

Snap bushings installed for the wire holes. New rivets installed on either side for re-enforcement. ![]() Wires attached with solder sleeves.

Wires attached with solder sleeves. ![]() Wires with braided sleeving and extra length as a service loop.

Wires with braided sleeving and extra length as a service loop.

Top Skin Riveting

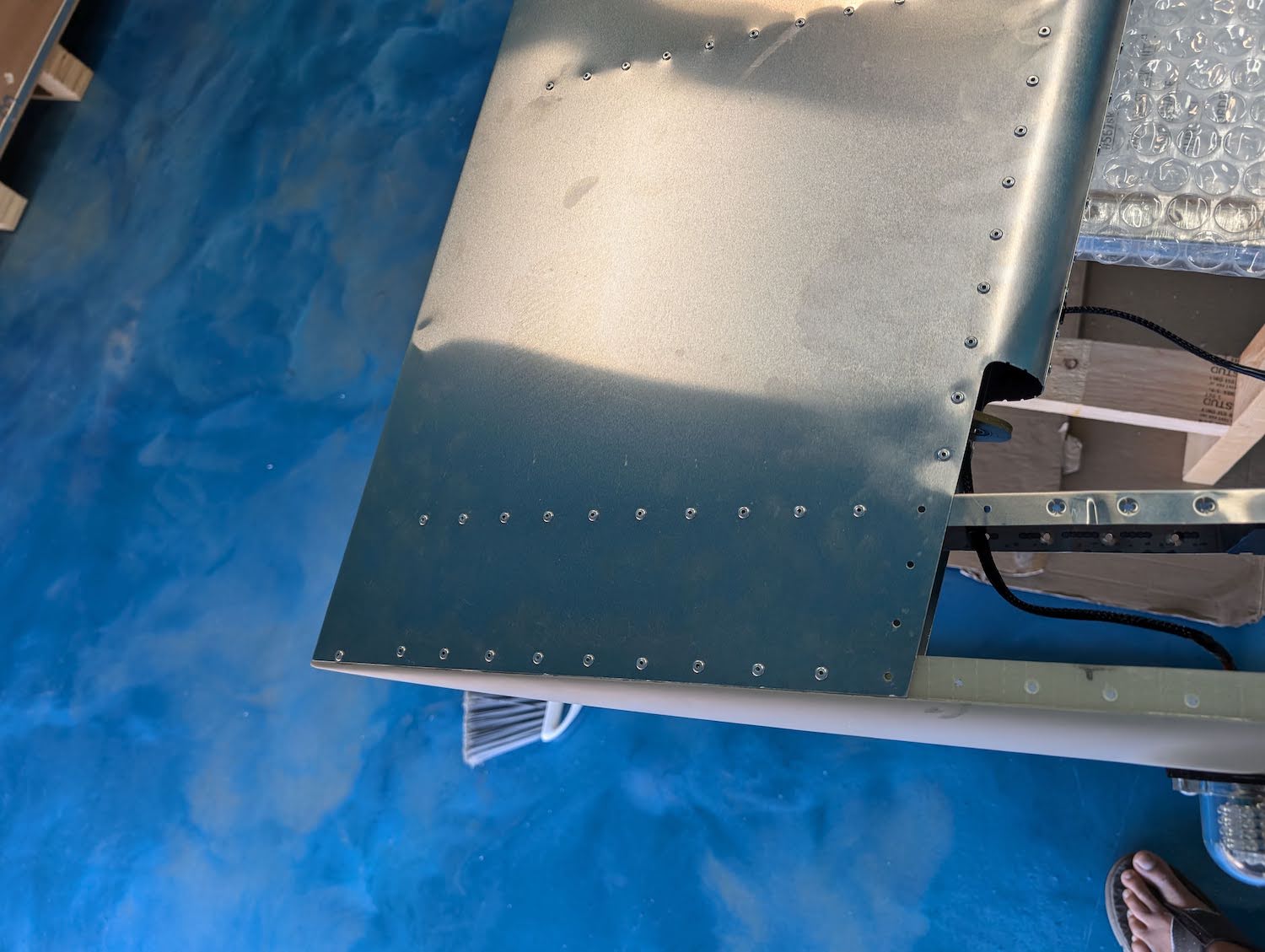

Riveting the top skin was pretty straightforward, some holes needed to be cleaned up using a 3.2mm drill bit. An extra rivet was added on both sides of the trailing edge for additional re-enforcement.  Top skin riveted (trailing edge).

Top skin riveted (trailing edge).  Top skin riveted.

Top skin riveted.  Top skin riveted.

Top skin riveted.

Avionics & Tools

Below are some avionics components, wiring components, and additional tools which were used for this process.

| Name | Description | Link |

|---|---|---|

| Red Tail Beacon | PSA Enterprise red tail beacon | https://www.aircraftspruce.com/catalog/elpages/model927anti.php |

| Wire Cutters | Micro wire snips for cutting | https://www.amazon.com/dp/B00FZPDG1K |

| Power Supply | 12v DC power supply for testing | https://www.amazon.com/dp/B09NVX48NT |

| Multimeter | For electrical connection testing | https://www.amazon.com/dp/B08MTTX66X |

| Braided Sleeving | For protecting electrical wires against chaffing | https://www.amazon.com/dp/B074GM1PK1 |

| Heat Gun | For using heat shrink butt connectors | https://www.amazon.com/dp/B08VFY8THD |

| Wire Connectors | Heat shrink butt connectors 18-22awg waterproof | https://www.amazon.com/dp/B0CVS3H3ST |

| 18awg Red Wire | Mil spec red wire 18awg for power | https://www.amazon.com/dp/B01MRXZA29 |

| 18awg Black Wire | Mil spec black wire 18awg for power (ground) | https://www.amazon.com/dp/B01MU185RP |

| Snap Bushing | For protecting electrical wires in a hole against chaffing | https://www.amazon.com/dp/B001BPV94E |

| High Heat Epoxy | For gluing rivnuts to the fiberglass tip | https://www.jbweld.com/product/high-heat-syringe |

| Step Drill Bits | For drilling a big size hole more gracefully | https://www.harborfreight.com/3-piece-titanium-nitride-coated-high-speed-steel-step-drills-91616.html |